Reasons to choose us

一、Features/Functions

1. Material Compatibility:Materials include: PVC, PET, silver plates, copper plates, acrylic sheets, two-color plates, composite aluminum nameplates, coated aluminum nameplates, coated stainless steel nameplates, coated cardboard certificates, heat shrink tubes, continuous labels, die-cut labels, aluminum foil labels, reflective signs, and various other materials for nameplate printing.

2. Outdoor Durability: Can withstand 5-8 years outdoors without fading.

3. Automatic Media Handling: Supports roll materials, single-sheet feeding, or panels, and also features automatic cutting for thin roll materials.

4. High Precision Positioning: Crucial for overprinting and printing markings on pre-formed nameplates.

5. Variable Data Printing: Supports data import for efficiently handling serial numbers, QR codes, barcodes, dates, batch numbers, and other unique information for each item.

6. High Resolution: Capable of printing very small characters that other machines cannot handle.

7. Powerful Software:· Compatible with various design file formats.· Database connectivity (for variable data).· Supports serialization and barcode generation.· Layout and template functions.· Color configuration and management.· Driver support for multiple operating systems.

8. Durability and Stability: Industrial-grade design suitable for long-term continuous operation.

9. Connectivity: USB interface for PC connection.

二、Application Scenarios

Wide range of applications: electricity, telecommunications, gas, water supply, industrial automation, electrical switchgear, railways, petrochemicals, landscaping, shipping, military, medical, fire protection, visual recognition, and other industries.

三、Core values

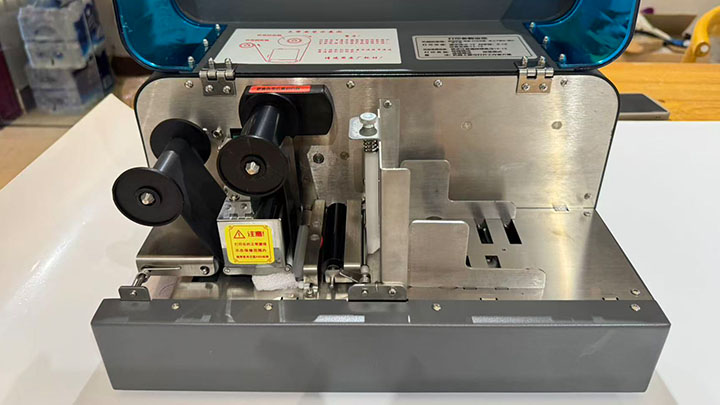

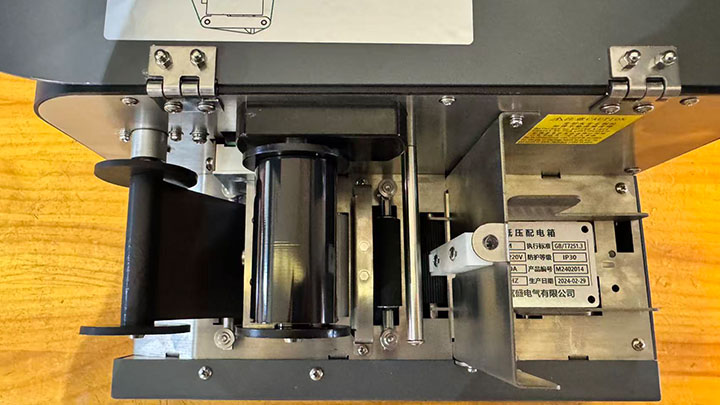

Night Hawk M680N Multifunction Nameplate PrinterIts core value lies in its flexibility and wide adaptability. It can replace multiple single-function devices, streamline workflows, reduce total ownership costs, and meet diverse needs ranging from simple asset labels to complex, highly durable industrial nameplates.

四、Craftsmanship Spirit:

We are nameplate printing experts. For 23 years, we have been committed to simplifying the production of industrial nameplate labels, promoting standardized labels in the power, telecommunications, and distribution panel industries, making our customers' products more refined and affordable. Our products include nameplate printers, nameplates, and labels.